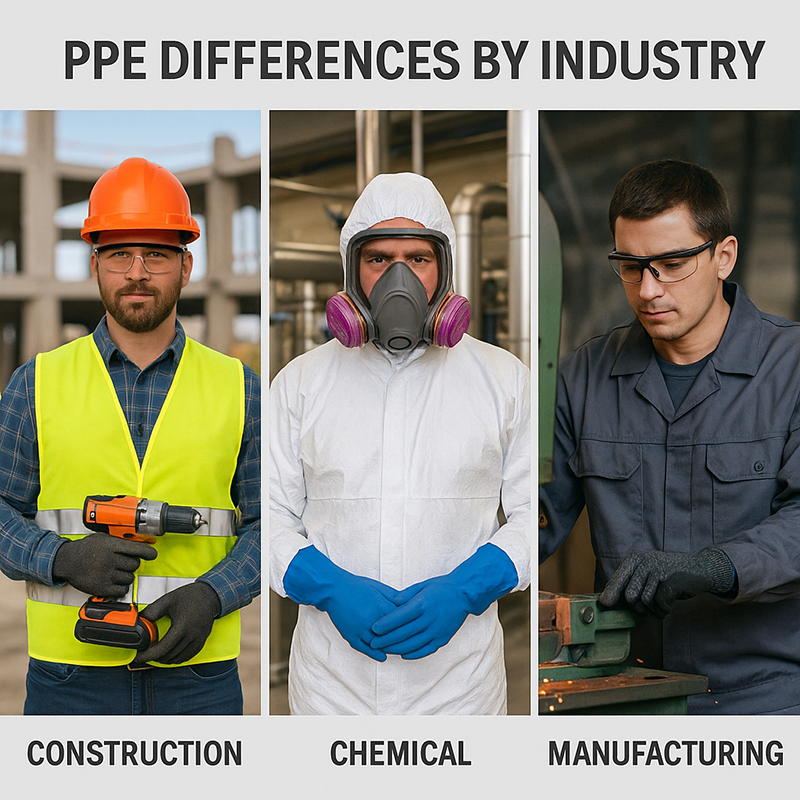

Personal Protective Equipment (PPE) is not one-size-fits-all. While its core purpose remains the same—protecting workers—different industries face different risks, and thus, require tailored solutions. Whether you’re in construction, chemical processing, or manufacturing, understanding the distinctions in PPE requirements is key to worker safety and compliance.

1. Construction: Physical Impact and Visibility Are Key

Common Hazards:

-

Falling objects

-

Sharp edges and tools

-

Heavy machinery

-

Dust, noise, and vibration

Essential PPE for Construction:

-

Hard hats (EN397) – for head protection

-

High-visibility vests (EN20471) – to ensure visibility in dynamic environments

-

Steel-toe safety boots (EN ISO 20345) – for foot protection

-

Cut-resistant gloves – for handling sharp materials

-

Hearing protection (earplugs or earmuffs) – for noise-intensive zones

-

Dust masks or particulate respirators (EN149) – especially during demolition or grinding

👉 Gonow Safety offers reflective clothing, impact gloves, and anti-puncture boots designed for construction workers.

2. Chemical Industry: Full Body Protection Against Liquids and Gases

Common Hazards:

-

Corrosive liquids and vapors

-

Toxic or reactive chemicals

-

Risk of splashes or inhalation

-

Potential for fire or explosion

Essential PPE for Chemical Handling:

-

Chemical-resistant coveralls (EN14605 or EN13034) – for full-body protection

-

Nitrile or butyl gloves (EN374) – resistant to a wide range of chemicals

-

Full-face respirators or SCBA (EN136) – when airborne risks are present

-

Chemical-resistant boots – prevent skin contact and corrosion

-

Splash goggles or face shields – to protect the eyes from chemical contact

👉Gonow Safety provides tested chemical suits, gloves, and SCBA systems tailored for high-risk environments.

3. Manufacturing: Balancing Safety and Comfort for Long Shifts

Common Hazards:

-

Sharp equipment and rotating machinery

-

Hot surfaces and molten materials

-

Repetitive tasks and ergonomic risks

-

Industrial noise and fine dust

Essential PPE in Manufacturing Plants:

-

Cut- or heat-resistant gloves – depending on specific tasks

-

Safety eyewear (EN166) – for protection from flying debris

-

Protective workwear – flame-retardant if needed (EN ISO 11612)

-

Hearing protection – especially in metalworking or machining areas

-

Slip-resistant footwear – to avoid workplace falls

-

Dust masks or respirators – for welding, sanding, or powder handling

👉 Our flexible, breathable PPE ensures long-hour comfort without compromising protection.

Why It Matters to Choose Industry-Specific PPE

Choosing the wrong PPE doesn’t just lower protection—it can increase risk. For instance:

-

Construction gloves won’t withstand acid spills in a lab.

-

A dust mask in a chemical plant might offer zero protection against toxic vapors.

-

Heavy suits in hot manufacturing zones can cause fatigue and reduce productivity.

That’s why Gonow Safety offers tailored PPE solutions designed with your work environment in mind. From oil-absorbent materials to SCBA units, we ensure your workers are protected with the right gear, in the right place.