When it comes to protective clothing, every detail matters — especially the label. The label on your coverall isn’t just a piece of fabric; it tells you whether you’re getting the right protection for your work environment. Understanding the numbers and symbols can help you choose the right PPE and stay safe on the job.

1. Why Coverall Levels Matter

Coveralls are classified into different protection levels to indicate how well they guard against liquids, particles, and biological hazards. Choosing the right level ensures workers are neither underprotected nor uncomfortable from over-specification.

-

Level 1–2: Suitable for low- to medium-risk environments, such as general maintenance or warehouse work.

-

Level 3–4: Designed for high-risk or hazardous settings, like laboratories, healthcare, or chemical handling.

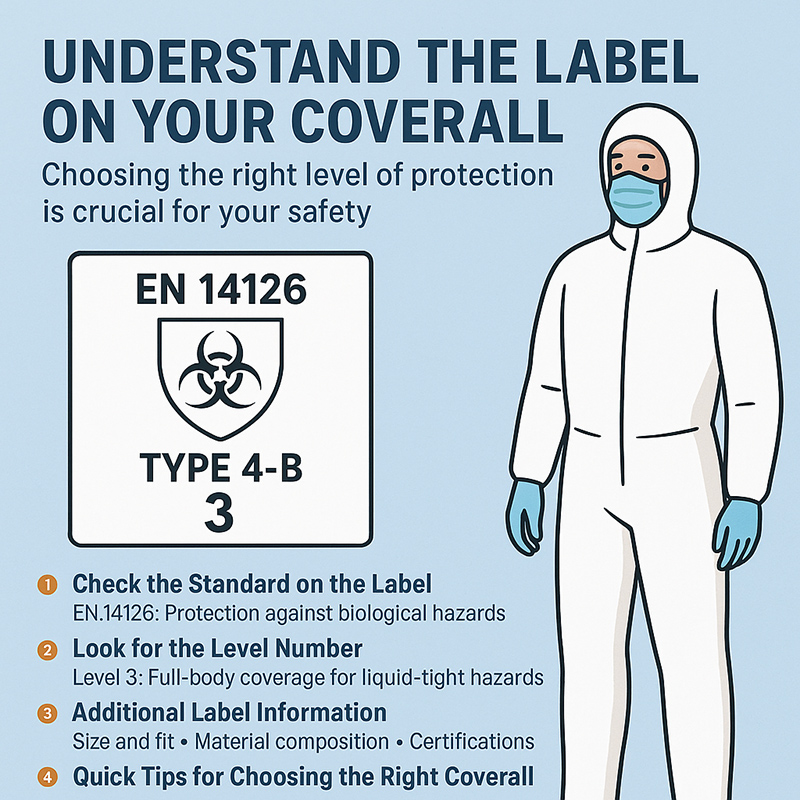

2. Check the Standard on the Label

Most coverall labels will reference a standard, such as:

-

EN 14126: Protection against biological hazards

-

EN 13034: Limited chemical splash protection

-

EN 14605 / EN 13982: Liquid-tight or particle-tight garments

These standards indicate the type of protection the coverall provides. A label referencing EN 14126 shows the garment has been tested for pathogens, while EN 13034 indicates chemical resistance.

3. Look for the Level Number

The level number (1–4) is usually printed on the label. It represents the garment’s protection capability:

-

Level 1: Minimal protection, lightweight and breathable

-

Level 2: Moderate protection for liquid splash or light chemical exposure

-

Level 3: Full-body coverage for liquid-tight hazards

-

Level 4: Maximum barrier protection, suitable for highly hazardous chemicals and infectious agents

Understanding this helps you match the garment to the risk level of your work environment.

4. Additional Label Information

Besides the level and standard, labels often include:

-

Size and fit — ensures comfort and proper coverage

-

Material composition — informs durability and breathability

-

Certifications — confirms third-party testing and compliance

5. Quick Tips for Choosing the Right Coverall

-

Always start with a risk assessment of your workplace.

-

Match the coverall level to the identified hazards.

-

Consider comfort and mobility — even the best protection won’t work if it hinders movement.

-

Don’t ignore the label — it’s your shortcut to safety compliance.

Conclusion

At Gonow Safety, we provide coveralls that are clearly labeled and fully compliant with international standards. By understanding the label, you can confidently select the right level of protection, keeping your team safe and comfortable on the job.