Comprehensive Understanding of EN 13688 Standard: Choosing the Right Workwear for Your Employees

EN 13688 is a European standard for protective workwear that ensures workers’ safety, comfort, and durability. By understanding this standard, businesses can make informed decisions when selecting workwear, ensuring optimal protection and productivity. This article dives deeper into the EN 13688 standard, helping you choose the right workwear for your employees.

1. What is the EN 13688 Standard?

EN 13688 is a European standard that sets the basic design, material, and performance requirements for protective workwear. The goal of this standard is to ensure that work clothing is durable, comfortable, and capable of protecting employees from a range of workplace hazards. While other industry-specific standards exist (such as EN 20471 for high-visibility clothing or EN 343 for waterproof workwear), EN 13688 is a general standard that focuses on overall workwear performance.

Key Details of EN 13688:

- Material Strength: Fabrics must meet a minimum tensile strength of 30 N per cm to ensure durability under physical stress.

- Breathability: Workwear must allow for moisture vapor to escape, ensuring comfort during prolonged use.

- Washing & Maintenance: Workwear must be able to withstand repeated washing without losing its protective capabilities.

Summary: EN 13688 ensures that workwear meets minimum quality and performance standards, offering protection and comfort across various work environments. This standard is essential for businesses aiming to protect their employees.

2. Core Requirements of the EN 13688 Standard

| Requirement | Description | Example |

|---|---|---|

| Materials & Durability | Workwear must be made from abrasion-resistant and tear-resistant fabrics. | Construction: Workwear made from high-strength fabrics like nylon or polyester to resist wear and tear from tools, heavy machinery, and rough surfaces. |

| Protection Performance | Workwear must protect against specific hazards (e.g., fire, chemicals, electrical hazards). | Chemical Plants: Workwear made from materials resistant to chemicals. Electrical Workers: Flame-resistant clothing to protect against electrical shocks. |

| Comfort & Suitability | Design should prioritize comfort and freedom of movement. Ergonomic features and breathable materials are essential. | Construction Workers: Breathable, well-tailored workwear to ensure comfort during long shifts in varying weather conditions. |

| Identification & Visibility | Workwear must include visible and reflective elements for safety in low-light conditions. | Road Workers/Warehouses: High-visibility jackets and vests with reflective strips for safety during early morning or night shifts. |

| Washing & Maintenance | Workwear must withstand repeated washing without losing its protective properties. | Frequent Wash Environments: Fabrics like polyester or cotton blends, known for durability and wash-resistance, ideal for workwear that needs frequent cleaning. |

Summary: Each core requirement ensures that workwear provides durability, comfort, and necessary protection in various work environments. By understanding these key points, you can make more informed decisions when selecting workwear for your team.

3. Why Is Choosing EN 13688 Compliant Workwear So Important?

Selecting EN 13688 compliant workwear is essential for protecting employees and complying with legal safety standards. Non-compliant workwear can result in increased workplace injuries, accidents, and even legal penalties for employers.

Key Benefits:

- Improved Safety: Compliance with EN 13688 reduces the risk of workplace injuries by ensuring adequate protection against physical, chemical, and electrical hazards.

- Enhanced Comfort: Compliant workwear is designed for comfort, reducing fatigue and improving focus during long shifts.

- Regulatory Compliance: Choosing EN 13688 compliant workwear helps your business meet European safety regulations, avoiding fines and legal issues.

Summary: EN 13688 compliant workwear not only improves safety and comfort but also ensures your business complies with essential workplace safety regulations.

4. How to Choose the Right Workwear Based on Work Environment

Different work environments present unique hazards that require specific types of protective workwear. Here’s how to choose the right workwear for your workplace:

Assess Hazards

First, assess the risks present in your workplace, including chemical spills, high temperatures, mechanical hazards, and more.

Example: In a chemical plant, workwear must protect employees from toxic spills, while construction sites require durable workwear to resist abrasions from rough surfaces.

Material & Design Selection

Once you’ve identified the risks, select workwear made from materials designed to provide the necessary protection. Choose features like flame-resistant fabrics for electrical work, or chemical-resistant materials for hazardous environments.

Example: Electrical workers need flame-resistant clothing to prevent injuries from electrical fires and shocks.

Comfort Considerations

Workwear must be breathable and well-fitted to ensure comfort. The right design will allow for freedom of movement without compromising protection.

Example: Workers in hot environments should wear moisture-wicking and breathable workwear to stay comfortable during long hours.

Summary: Properly assessing the hazards of your work environment is essential in choosing workwear that provides the right protection, comfort, and durability.

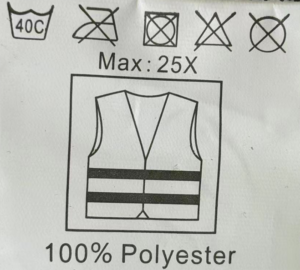

5. How to Identify EN 13688 Compliant Workwear?

When selecting workwear, ensure it has the correct certification marks, such as the CE mark or EN 13688 logo. These marks guarantee that the workwear meets European safety standards and is compliant with the EN 13688 regulations.

Summary: Always verify that workwear displays proper certification marks to ensure it meets the EN 13688 standard for quality and safety.

6. How to Extend the Lifespan of Workwear?

To get the most out of your workwear, it’s essential to follow the manufacturer’s care instructions and conduct regular inspections. Proper maintenance ensures that workwear retains its protective qualities and lasts longer.

- Washing & Care: Always wash workwear according to the manufacturer’s instructions to prevent damage and maintain its protective properties.

- Regular Inspections: Periodically check for wear and tear, especially in high-stress areas such as knees, elbows, and seams.

Summary: Regular care and maintenance of workwear will extend its lifespan, ensuring it remains functional and protective.

Visual Comparison of Materials and Their Protective Performance

| Material | Abrasion Resistance | Waterproof | Breathability | Fire Resistance |

|---|---|---|---|---|

| Polyester | High | Medium | High | Low |

| Nylon | Medium | High | Medium | Medium |

| Cotton | Low | Low | High | High |

Conclusion: Start with Choosing the Right Workwear to Ensure Employee Safety

When choosing workwear, understanding the EN 13688 standard is essential for ensuring both safety and comfort. By selecting compliant workwear, businesses can protect employees from workplace hazards and improve overall productivity.

Have Questions? If you’re unsure about how to select the right workwear for your business, contact Gonow Safety today. Our experts will provide tailored recommendations based on your specific needs.

Let’s Discuss! What challenges have you faced in selecting workwear for your team? Share your thoughts in the comments below, and let’s continue the conversation.