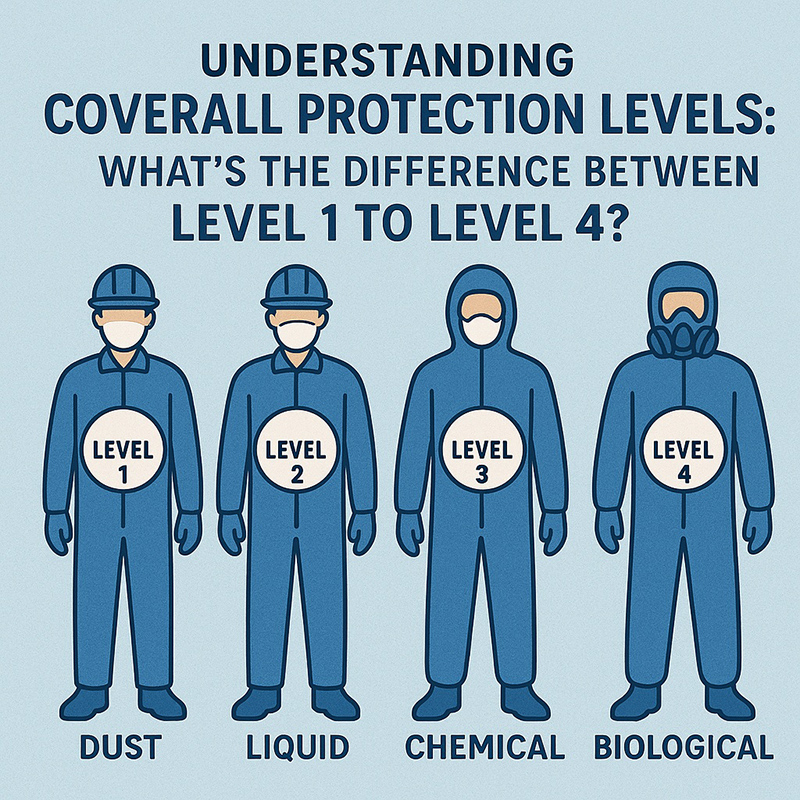

When it comes to protective coveralls, not all garments offer the same level of protection. Different working environments and hazards require different standards. Understanding the coverall protection levels — from Level 1 to Level 4 — can help you choose the right one for your needs.

What Do the Levels Mean?

Coverall protection levels are commonly defined under the ANSI/AAMI PB70 standard, which classifies garments based on their ability to resist liquid penetration.

The higher the level, the stronger the protection against liquid and fluid exposure.

| Level | Protection Performance | Typical Applications | Notes |

|---|---|---|---|

| Level 1 – Minimal Protection | Provides basic barrier for light, non-hazardous exposure. | Routine patient care, basic cleaning, general inspection. | Lightweight, breathable, comfortable — but not suitable for liquid spray or pressure exposure. |

| Level 2 – Low Protection | Offers low-level fluid resistance for light exposure to liquids or aerosols. | Laboratory work, basic maintenance, handling non-toxic chemicals. | Slightly higher protection; still not for heavy liquid exposure. |

| Level 3 – Moderate Protection | Protects against moderate fluid exposure and light sprays. | Procedures with fluid contact, disinfection work, industrial cleaning. | Balances comfort and protection well; suitable for environments with limited liquid spray. |

| Level 4 – High Protection | Highest level of protection against heavy liquid exposure and pressurized fluids. | Chemical handling, high-risk environments, infectious control. | Maximum protection, but less breathable and may reduce comfort during long use. |

Choosing the Right Level

Selecting the right coverall level depends on your specific work environment and the types of hazards you face. Here are a few key factors to consider:

-

Type of Hazard

-

Light dust or dry particles → Level 1–2

-

Liquid splash or low-pressure spray → Level 2–3

-

High-pressure spray, hazardous liquids, or infectious risks → Level 4

-

-

Duration of Exposure

Long-term use may require breathable fabrics or ventilation panels to reduce heat buildup, especially in higher-level coveralls. -

Comfort and Mobility

Higher protection levels typically use denser fabrics, which reduce breathability. Look for designs with ergonomic cuts or breathable backs for comfort. -

Additional Features

-

Sealed seams or taped seams enhance barrier performance.

-

Elastic wrists, ankles, and hoods help prevent liquid entry.

-

Antistatic and lint-free materials improve safety in sensitive environments.

-

Coverall Levels vs. Other Standards

Besides ANSI/AAMI PB70, other global standards also classify coveralls by performance, such as:

-

EN 14126 (for biological hazards)

-

EN 14605 / Type 3–4 (for liquid chemical protection)

-

EN 13982 / Type 5 (for dry particle protection)

-

EN 13034 / Type 6 (for light chemical spray)

While names differ, the concept remains the same: a higher type or level number usually means better protection against liquids or hazardous materials.

How to Get the Most Out of Your Coveralls

-

Inspect before each use — check for tears, seam damage, or contamination.

-

Choose the right size — poor fit can reduce protection and comfort.

-

Combine with appropriate PPE — gloves, respirators, and footwear should match the protection level of your coverall.

-

Dispose properly — follow local safety and disposal regulations after use, especially in contaminated environments.

Final Thoughts

Understanding the difference between Level 1 to Level 4 coveralls is essential for selecting the right PPE.

Each level serves a specific purpose — from light-duty tasks to high-risk operations.

The key is to balance protection, comfort, and performance to ensure both safety and efficiency in your workplace.